Questions and Answers on our encapsulating products

Coloured or transparent?

Well, it depends on many factors, especially from each countries’ national laws: the applicable legislation in the matter in our country (Italy) states that every product must have a different and contrasting colour from eachother, in order to reveal any possible sign of deterioration immediately. The italian law being this strict, we are equipped to provide our products in every possible colour, in order to always have a perception of the possible weariness on any of our applied products directly on the surface.

The top caoating layer is, in fact, exposed to weather changes and thus it wears off during time, promptly showing the layer underneath, which is of a highly contrasting colour. In this way any wearing off of the exposed finish is easily identifiable.

How long does an incapsulant product take to dry?

Well, for waterbased encapsulants the average drying time depends also on weather related factors, in any way we have estimated that, with an average temperature of about 23 °C and a relative 60% environmental moisture condition our products will be perfectly dry in about 30 minutes.

How long after i can paint over the encapsulation coatings i just laid?

Waterbased encapsulating products, applied on porous surfaces like, for example, an eternit slab, with an average temperature of about 23 °C and a relative 60% environmental moisture condition, you can repaint right after 12 hours.

Every one of our single component products is repaintable even after a long time, right after a preventive cleaning.

Before repainting a surface already treated with our encapsulants, though, it is for the best to verify the compatibilityof the two compounds, by checking that the coating chosen to repaint is a high elasticity module one, as our coatings are.

What’s the coverage for an encapsulation coating?

It is necessary to distinguish between products for accessory encapsulations and for conservative encapsulations. In the first case the average coverage is 5-8 m2 per litre, in the second case, where the product is concentrated and has to be diluted, the coverage is at least doubled. Nonetheless, due to the fact that most surfaces are aged, porous and often friable, the coverage might be reduced depending on the condition of aforesaid surfaces.

In Italy, though, the law sets the standard thickness for coating products: 300 micron for an outdoors finishing, 250 micron for indoors and 200 micron for coating over an already treated surface.

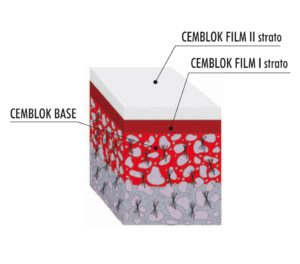

In order to guarantee these requirements we advise to use at least 650g/m2 of Cemblok Film A in case of encapsulation exposed outdoors, 550 g/m2 in case of encapsulations exposed indoors and, finally, 500 g/m2 in case of coating treated surfaces.

What spray pumps can I use to lay the product?

The spray pumps indicated by the appliable legislation are airless system spray pumps, or to clarify, pumps without a compressor, in this way the product can be spread on surfaces without any risk of moving any asbestos fibres in the process.

How much does an airless pump cost?

There are all kinds of airless spray pums, ranging froma price of 700€ to one of 7000€. In any case to apply encapsulating materials of low viscosity, like those products that are used to coat asbestos in order to remove it, a pump costing among 700€ and 1000€ should be enough. Nonetheless, in order to spread higher viscosity products, like the preservative encapsulants, you need to invest at least 1500€ for a more complex and powerful pump.

Is it worth it to buy one or is it more convenient to rent one?

Very often, decontaminating companies ask themselves this question, we always advise to resort to either buying or selling, based on how many jobs of this kind you foresee in the future: considering that the renting costs are set at about 80-100€ per day, if you don’t work more than 2 or 3 jobs of the kind per year, it is advisable to resort to renting.

Is encapsulation long lasting? How long does this kind of treatment last?

It depends, it can last for 20 years even if it’s indoors, up to 10 years outdoors. Important conditions to always meet in order for our products to correctly adhere to any surface are: treat a clean and robust surface; the surface must have the right orientation for water and rain to flow correctly and prevent backwater; ordinary mainteinance operations must be executed when needed.

What’s the difference between compact and friable asbestos?

Under the friable asbestos category fall all those manufactured products that are easily pulverised or turned into fragments by hand, whereas are classified as compact all those that to achieve the same results require the use of mechanic tools, scalpels, disk sanders and so on..

What’s the difference between a PCM Analysis and a SEM analysis?

The PCM Analysis, or Phase-Contrast Microscope Analysis is a quantitative analysis that the lab technicians produce by counting the total number of fibers captured in the filter, then distinguishing between asbestos fibres and others.

The Scanning Electron Microscopy is a much deeper analysis with an higher resolution than the PCM Analysis, because it makes us able to determine the quantity of fibres, their quality and concentration (fibres per volume) and, moreover, it allows us to analyze also different substances such as terrain, water, waste and so on…

Are your encapsulants resistant to rain?

Every preservative encapsulant is resistant to rain, but those of the D type, destined to coat parts to remove are much different: very often when destined to this application, cheap products are sold, with a low concentration and therefore with a very low rain resistance, and they are subject to washout.

we offer two high-technology developed encapsulant, both with low viscosity and in very strong colorations: they can last for months under the rain. Cemblock Base WR, which must be diluted, and Cemblok Base Performance, ready for use.

How do I clean off encaplunts stains and underised dirt?

Once dry, our encapsulants produce two kinds of dirt: the first one is the resin when it hardens, and the colour’s pigment. Given that the surface allow it, the first treatment involves using hot water and a heavy-duty steel wool, or high using a high pressure water jet, in any case the temperature must be higher than 80 °C, this will leave a possible colour stain that can easily be removed by applying bleach and leaving it to act on the stain for a few hours.

How do I apply an encapsulant product?

Given that the surface must be dry and preventively prepared for the treatmjent, the best way of application is by means of airless pumps, we advise you to always spread the treatment with 2 coats, one perpendicular to the other in order to achieve a homogenous effect, even on corrugated sheets, as is in the case of eternit slabs.

The pros and cons of encapsulation

Preservative encapsulation is a choice that allows to secure the structure with cost-effectiveness and quicky; the only downside of the procedure is that the asbestos-containing material has not been removed, a thing which is always to keep into consideration as a future expense.

How much does encapsulation cost?

The cost of encapsulating a structure varies from half to a third of the cost that would involve a removal of the aforesaid. This statement is in place whenever we schedule to substitute the preexisting roof with a metallic roofing or with new sandwich panels. In contrast, if the structure is demolished after the removal of the asbestos roof the costs of encapsulation are similar to those of removal.

Encapsulation’s products fire reaction classes

Our encapsulants, not having any particular additives in that regard, have a low reaction class, they are marked as F class.

Y Beams Protection, and why it’s necessary

Whenever you execute a reclamation of asbestos slabs , the “eternit” compound must be thoroughly removed, then a new metallic sheet is used as a cover for the slab. After that, a routeing system must be carved, in order to allow the necessary flows of water and rain, the problem in this event, is that more than often, it is not a common practice to verify the state of conservation of the concrete beams, which have been exposed to the weather for many years.The most common case you may find is tied to prestressed concrete beams, commonly referred to as Y Beams. This kind of structure, being very strong on the core, tends to be weaker on the wings, which are made of thinner concrete, with thin layers of the material to cover their iron skeleton, therefore they are subjected to carbonation and breaking.