CARBONATION PROTECTION FOR Y BEAMS

Whenever you execute a reclamation of asbestos slabs , the “eternit” compound must be thoroughly removed, then a new metallic sheet is used as a cover for the slab. After that, a routeing system must be carved, in order to allow the necessary flow of water and rain, the problem in this event, is that more than often, it is not a common practice to verify the state of conservation of the concrete beams, which have been exposed to the weather for many years.The most common case you may find is tied to prestressed concrete beams, commonly referred to as Y Beams. This kind of structure, being very strong on the core, tends to be weaker on the wings, which are made of thinner concrete, with thin layers of the material to cover their iron skeleton, therefore they are subjected to carbonation.

The penetration of co2 into the concrete start the process of carbonation in the aforesaid, that is the Ph levels lower drastically, depriving the reinforcing rods of their natural anti-corrosive protection. The result of this, is that the concrete progressively tends to lose its coherence and its mechanical resistance decreases more and more. This causes a condition, clearly shown in the pictures on the side, or in the edges of old balconies that due to this phenomenon tend to split drastically.

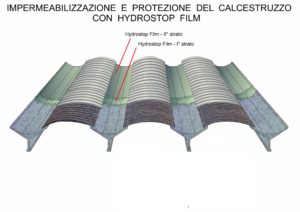

In cases like the one in the picture, the only possible solution could be the substitution of the supporting beams, yet to prevent this kind of situation, it is possible to use a product in order to protect the beam and avoid carbonation altogether: the HYDROSTOP FILM®.

- The application of Hydrostop Film® can be used to prevent the effects of carbonation on beams. The application procedure is very simple, in order to obtain a protective film on the concrete first apply a coat of HYDROSTOP FILM® with 1.1 dilution as a primer on the treated area, and then lay a thicker second layer of the product on the primed surface.